Compression Testing Machine

Compression Testing Machine Specification

- Product Type

- Compression Testing Machine

- Weight

- 50-150 Kilograms (kg)

- Voltage

- 220 Volt (v)

- Material

- Mild Steel

- Application

- Laboratory

- Warranty

- 1 Year

Compression Testing Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T)

- Supply Ability

- 2 Pieces Per Month

- Delivery Time

- 1 Week

- Main Export Market(s)

- Asia, Australia, North America, Eastern Europe, Middle East, Central America, South America, Western Europe, Africa

- Main Domestic Market

- All India

About Compression Testing Machine

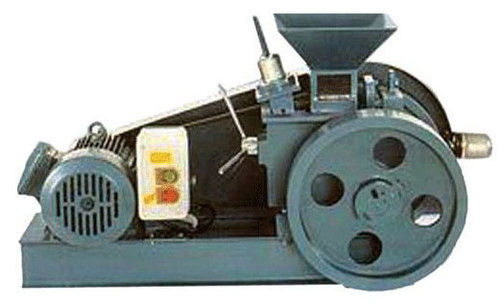

Compression Testing Machine -Capacity: 50 Tone

Strength of Concrete is a very important aspect during construction. Strength of concrete is obtained by crushing the specimen in from of cubes or cylinders. Engineers carefully design concrete for a particular compressive strength and specimen is tested by applying load in a compression Testing Machine. Where carrying frequently the specimens for testing in a standard laboratory is inconvenient and uneconomical.Complete with special attachments, the machines can also be used for bricks. Hallow or solid concrete blocks, using appropriate capacity machine. In general a Compression Testing Machine consists of Load Frame with suitable platens and a Pumping Unit with Pressure gauge, either had operated or electrically cum hand operated. Load frame and Pumping unit are connected by pressure pipes.

Precision in Material Testing

This compression testing machine ensures precise determination of compressive strength for a wide range of materials. Engineered in mild steel, it is ideal for laboratory environments seeking reliable analytical results. The machines robust structure contributes to consistent performance and dependable outcomes.

Versatile Distribution and Support

Available via distributor, exporter, manufacturer, supplier, and trader channels across India, the machine ensures widespread accessibility and prompt service. The 1-year warranty guarantees assistance for maintenance and queries, providing peace of mind to laboratories nationwide.

FAQs of Compression Testing Machine:

Q: How does the compression testing machine operate in a laboratory setting?

A: The compression testing machine operates by applying controlled compressive force to test specimen materials, enabling laboratories to evaluate their strength and durability. The system is powered by a standard 220-volt supply, ensuring compatibility with typical lab equipment.Q: What types of materials are typically tested with this machine?

A: This equipment is suitable for testing a variety of construction and engineering materials, such as concrete, bricks, and other samples, to determine their compressive strength and structural performance.Q: When is calibration or maintenance required for the compression testing machine?

A: Routine calibration and maintenance are recommended at regular intervals, typically every six months, or as per laboratory protocol, to ensure precise testing outcomes and optimal machine functionality.Q: Where can I purchase or obtain support for this testing machine in India?

A: The compression testing machine is available through distributors, exporters, manufacturers, suppliers, and traders throughout India. Additionally, customers can access support and after-sales service via these authorized channels.Q: What is the process of using the compression testing machine for material analysis?

A: Firstly, the specimen is placed securely in the testing chamber. The operator then initiates the compression cycle, gradually increasing load until the sample fails. The machine accurately records compressive strength values for analysis.Q: How does the 1-year warranty benefit users of the compression testing machine?

A: The included 1-year warranty covers manufacturing defects and service support, ensuring users receive timely assistance and repairs during the warranty period for hassle-free operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SOIL TESTING EQUIPMENTS Category

Soil Mechanics Lab

Price 125000 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Laboratory

Material : Stainless Steel

Warranty : 1 Year

Ductility Testing Apparatus

Price 46000 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Laboratory

Material : Stainless steel

Warranty : 1 Year

Vibrating Table

Price Range 15000.00 - 25000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Laboratory

Material : Steel

Warranty : 1 Year

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry