Call: 08071930543

Tensile Testing Machine

MOQ : 1 Piece

Tensile Testing Machine Specification

- Control Type

- Digital / Manual

- Display Type

- Digital Display

- Features

- High precision, Robust frame, Easy operation

- Accuracy

- 1% of indicated load

- Shape

- Rectangular

- Power Supply

- AC Mains

- Speed Range

- 50 - 500 mm/min

- Temperature Resistance

- Up to 50C

- Type

- Tensile Testing Machine

- Dimension (L*W*H)

- Approx. 1200 x 600 x 1800 mm

- Product Type

- Testing machine

- Weight

- 100-200 Kilograms (kg)

- Equipment Materials

- Stainless Steel Construction

- Power

- 1 HP Motor

- Voltage

- 230-240 Volt (v)

- Material

- Stainless Steel

- Application

- Laboratory

- Test Modes

- Tensile, Compression, Flexural

- Grip Type

- Interchangeable Grips

- Equipment Type

- Testing machine

- Operation

- Automatic / Semi-Automatic

- Safety Features

- Overload Protection, Emergency Stop

- Load Capacity

- Up to 5000 kgf

- Testing Standards

- Complies with ASTM, ISO

- Crosshead Travel

- Up to 1000 mm

- Paint Finish

- Powder Coated

- Data Output

- USB and RS232 connectivity

Tensile Testing Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T)

- Supply Ability

- 1 Piece Per Month

- Delivery Time

- 1 Week

- Main Export Market(s)

- Western Europe, Asia, South America, Eastern Europe, Middle East, Central America, North America, Australia, Africa

- Main Domestic Market

- All India

About Tensile Testing Machine

Tensile Testing Machine-This machine is electrically operated machine for testing tensile strength and elongation of material like plywood, wires, cables, conductors, ferrous and non ferrous material. Specifications:- Capacity: 2500 N Range: 0-2500 N x 0.5 Traverse speed: 300 and 100mm Grip separation: minimum: 25mm Grip separation: maximum: 1000mm Power requirement: 3 ph 440V 50 Hz AC Over travel Safety Switches: Included |

Versatile Testing Capabilities

This machine supports multiple test modes such as tensile, compression, and flexural strength assessments, making it ideal for a variety of materials and applications. With interchangeable grips and compliance with ASTM and ISO standards, it ensures accurate, repeatable results across diverse testing requirements.

Superior Safety and Durability

Safety measures include overload protection and an emergency stop function to mitigate risks during testing. Constructed from stainless steel and finished with powder coating, the machine offers longevity and robust resistance to operational wear, aligning well with the demands of professional laboratory environments.

Streamlined Operation and Data Management

Equipped with digital and manual control options, the machine offers both automatic and semi-automatic operations for user convenience. Test data can be easily exported through USB or RS232 connectivity, facilitating seamless analysis and reporting for quality assurance or research purposes.

FAQs of Tensile Testing Machine:

Q: How does the Tensile Testing Machine ensure accurate measurement results?

A: The machine is equipped with a high precision digital load cell and advanced electronics that provide accuracy within 1% of the indicated load. It meets international ASTM and ISO testing standards, and its robust stainless steel construction minimizes deflection during testing.Q: What is the process for conducting a test on this machine?

A: Begin by selecting the appropriate interchangeable grip for your material, secure the specimen, and configure the testing parameters on the digital display. Once the machine is started, it automatically controls speed and records data, ensuring efficient and repeatable results.Q: What safety features are integrated into the system?

A: Safety features include overload protection, which prevents erroneous results or equipment damage if excessive force is detected, and an emergency stop button that immediately halts all operations to protect users and specimens.Q: Where can this tensile testing machine be used effectively?

A: This equipment is ideally used in laboratory settings for quality control, research, and material development. Its compliance with international standards and robust construction make it suitable for industrial manufacturers, exporters, research institutions, and academic laboratories in India.Q: When should I choose the automatic versus semi-automatic operation?

A: Opt for automatic operation for standardized, repetitive tests to increase efficiency and consistency. Use semi-automatic mode when custom test parameters or more hands-on control are required for unique or complex specimens.Q: How do I export data from the machine?

A: Test data can be easily exported using either the USB port or RS232 interface, allowing direct transfer to computers or data management systems for analysis, archiving, and reporting.Q: What benefits does the stainless steel construction provide?

A: Stainless steel construction ensures the machine is highly resistant to corrosion and mechanical wear, providing long-term reliability and precision even with frequent use in demanding laboratory environments.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in SOIL TESTING EQUIPMENTS Category

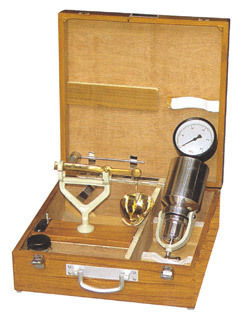

Speedy Moisture Meter

Price Range 5000.00 - 25000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Steel

Application : Laboratory

Warranty : 1 Year

Triaxial Shear Test Apparatus (Motorized)

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Mild Steel

Application : Laboratory

Warranty : 1 Year

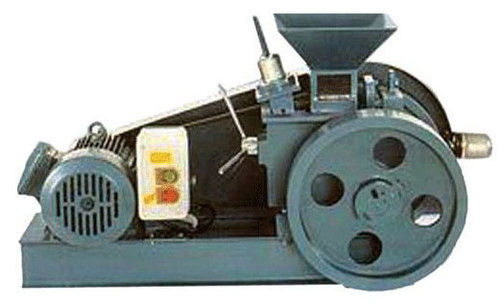

Ductility Testing Apparatus

Price 46000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless steel

Application : Laboratory

Warranty : 1 Year

"We are accepting only bulk quantity orders."

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry