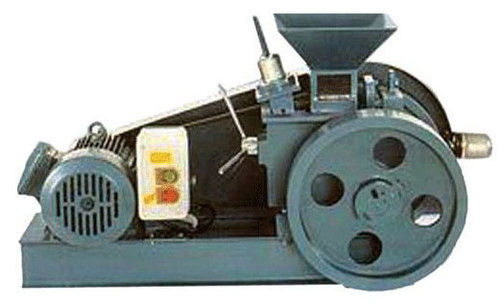

JAW CRUISHER

JAW CRUISHER Specification

- Features

- Heavy Duty, Low Maintenance, Robust Construction

- Control Type

- Manual

- Speed Range

- 300-400 rpm

- Temperature Resistance

- Up to 100C

- Shape

- Rectangular

- Display Type

- Analog

- Accuracy

- 1 mm

- Power Supply

- Three Phase

- Usage

- Use For Laboratory

- Type

- Jaw Crusher

- Dimension (L*W*H)

- 1050 mm 550 mm 960 mm

- Equipment Type

- Crusher

- Equipment Materials

- Mild Steel

- Power

- 7.5 HP

- Voltage

- 440 V

- Material

- Mild Steel

- Application

- Laboratory

- Capacity (Ltr)

- 350 Kg/Hr

- Jaw Plate Material

- Manganese Steel

- Drive Type

- Electric Motor

- Max Feeding Size

- 90 mm

- Discharge Size

- 10-25 mm

- Frame Material

- Mild Steel

- Operation Mode

- Semi-Automatic

- Weight

- 550 Kg

- Noise Level

- Less than 85 dB

- Feed Size

- 100 mm x 150 mm

- Lubrication Type

- Grease

- Crushing Capacity per Hour

- 350 Kg

JAW CRUISHER Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T)

- Delivery Time

- 1 Week

- Main Export Market(s)

- Eastern Europe, Middle East, Central America, South America, Western Europe, Asia, North America, Australia, Africa

- Main Domestic Market

- All India

About JAW CRUISHER

Jaw Crusher

We are provide a precision designed range ofJaw Crushers.Compact in design and durable, these crushers are manufactured to speed up crushing of aggregate, ores, mineral, coal and similar materials. Suitable for laboratory and small production units, these are offered with adjustable manganese steel jaws, motor, starter, switch and V belt.

Specification:

Capacity: 500kg

Size: 6 x 8

Maximum Feed: 50 60mm

Out put 6 20mm

Power Supply 3hp 3Phase

Precision Crushing for Laboratory Applications

Crafted for the precise reduction of sample materials, this jaw crusher is ideal for laboratories conducting material analysis or quality control. The device ensures thorough, consistent crushing of samples with a selectable discharge size (10-25 mm), making it an essential tool for accurate testing and research.

Durable Construction and Low Maintenance

Built with a mild steel frame and manganese steel jaw plates, this crusher stands up to rigorous lab environments. Its robust construction, grease lubrication, and user-friendly manual controls minimize upkeep, ensuring uninterrupted, cost-effective operation for researchers and technicians alike.

FAQs of JAW CRUISHER:

Q: How does the jaw crusher operate in a laboratory setting?

A: The jaw crusher is designed for semi-automatic operation, allowing users to manually adjust settings and load materials. Simply feed material (up to 90 mm in size) into the 100 mm x 150 mm jaw opening, and the electric motor drives the jaws to crush samples efficiently, with a discharge size between 10 and 25 mm.Q: What materials are best suited for processing in this jaw crusher?

A: This jaw crusher excels in crushing various laboratory samples, especially hard materials like ores, minerals, and rocks. Its manganese steel plates and robust frame are engineered for durability and precision, making it suitable for research, testing, and sample preparation.Q: When should the jaw plates and lubricants be checked or replaced?

A: Regular inspection of the manganese steel jaw plates and grease lubrication is recommended after prolonged or heavy usage. Typically, checks should be conducted monthly, and replacement or replenishment should follow manufacturer guidelines, especially when you notice reduced efficiency or uneven crushing.Q: Where can this jaw crusher be installed within a laboratory?

A: The crushers compact rectangular shape (1050 x 550 x 960 mm) allows for easy installation on laboratory workbenches or dedicated stands. Ensure placement near appropriate power sources (440 V, three-phase) and adequate ventilation, away from moisture and direct heat sources.Q: What is the step-by-step process for using the jaw crusher?

A: To operate, select the desired discharge size, power on the device, and manually feed material into the jaw opening. Monitor the analog display for operating status. After crushing, collect the processed material and switch off the machine. Routine cleaning and lubrication after each cycle ensure optimal performance.Q: How does the crusher benefit laboratory operations?

A: With a high throughput of 350 kg/hr, reliable precision (1 mm accuracy), and low noise (<85 dB), this jaw crusher streamlines sample preparation. Its robust, low-maintenance design assures researchers of safe, consistent, and efficient laboratory workflows.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SOIL TESTING EQUIPMENTS Category

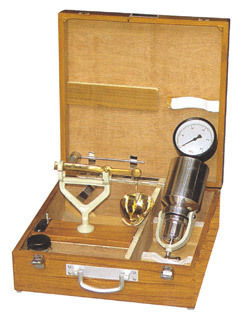

Speedy Moisture Meter

Price Range 5000.00 - 25000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Steel

Application : Laboratory

Warranty : 1 Year

Product Type : Moisture Meter

SIEVE SHAKER MOTORISED

Price Range 250000.00 - 50000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Mild Steel

Application : Laboratory

Warranty : 1 Year

Product Type : Shaker

Aggregate Impact Tester

Price Range 5000.00 - 15000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : : Stainless steel

Application : Laboratory

Warranty : 1 Year

Product Type : Impact Tester

TEST APPRATUS

Price Range 15000.00 - 30000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Material : Stainless steel

Application : Laboratory

Warranty : 1 Year

Product Type : Apparatus

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry