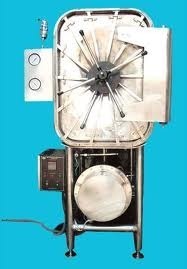

Vertical Autoclaves

Vertical Autoclaves Specification

- Material

- Stainless Steel

- Weight

- 50-70 Upto Kilograms (kg)

- Power

- 50 Watt (w)

- Application

- Industrial

- Usage

- Use For Industrial And Laboratory

- Product Type

- Autoclave

- Voltage

- 240 Volt (v)

Vertical Autoclaves Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Letter of Credit at Sight (Sight L/C)

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 1 Week

- Main Export Market(s)

- Western Europe, Australia, North America, South America, Eastern Europe, Middle East, Africa, Central America, Asia

- Main Domestic Market

- All India

About Vertical Autoclaves

Our vertical autoclave are widely used sterilization procedures and in various laboratory application.These autoclaves are manufactured from quality materials thus providing maximum satisfaction to our clients.Comprehensive Sterilization Solution

Vertical Autoclaves deliver powerful and consistent sterilization, ideal for industrial and laboratory settings in India. Their stainless steel construction ensures longevity and resistance to corrosion, while the design allows for easy loading and unloading. Equipped with user-friendly controls, these autoclaves offer efficient operation and precision in temperature regulation, ensuring effective results every cycle.

Key Operational Features

Operating at 240 volts and requiring 50 watts of power, these autoclaves offer energy-efficient performance without compromising sterilization quality. Suitable for handling a range of laboratory and industrial items, their capacity accommodates various loads. The vertical design saves space and facilitates convenient installation in both compact and larger work environments.

FAQs of Vertical Autoclaves:

Q: How does a vertical autoclave function in laboratory and industrial settings?

A: A vertical autoclave works by using high-pressure steam to sterilize instruments, glassware, and materials. It provides consistent temperature control and pressurization, ensuring effective sterilization for both laboratory experiments and industrial production processes.Q: What are the advantages of using stainless steel for vertical autoclaves?

A: Stainless steel offers excellent durability, corrosion resistance, and longevity. It ensures that the autoclave can withstand frequent use, high temperatures, and moisture, making it ideal for rigorous laboratory and industrial applications.Q: When is it necessary to use a vertical autoclave in industrial and laboratory environments?

A: Vertical autoclaves are essential whenever sterile conditions are required for tools, samples, or production materials, such as before microbiological testing, surgical procedures, or manufacturing activities that demand contamination-free equipment.Q: Where can vertical autoclaves be sourced in India?

A: Vertical autoclaves can be obtained from a range of suppliers, distributors, exporters, manufacturers, and traders across India who specialize in laboratory and industrial equipment, ensuring easy accessibility for diverse sectors.Q: What is the process for operating a vertical autoclave?

A: The process typically involves loading the items, adding requisite water, sealing the lid securely, setting the required temperature and cycle time, and initiating the power. After sterilization, items can be safely unloaded once cooling and pressure normalization occur.Q: How much power and voltage are required for vertical autoclaves?

A: These autoclaves operate efficiently at 240 volts and consume 50 watts of power, striking a balance between energy efficiency and robust sterilization capability.Q: What are the main benefits of using a vertical autoclave in industrial and laboratory applications?

A: Main benefits include rapid and thorough sterilization, robust construction for frequent use, minimal maintenance requirements, and the ability to handle a variety of loads, all crucial for effective operations in demanding environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in AUTOCLAVES Category

Horizontal Autoclaves

Price Range 50000.00 - 90000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Autoclave

Usage : Use For Industrial And Laboratory

Application : Industrial

Voltage : 240 Volt (v)

Table Top Autoclaves

Price Range 20000.00 - 80000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Product Type : Autoclave

Usage : Use For Industrial And Laboratory

Application : Industrial

Voltage : 240 Volt (v)

Horizontal Rectangular Autoclave Deluxe Model

Price Range 30000.00 - 300000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Autoclave

Usage : Use For Industrial And Laboratory

Application : Industrial

Voltage : 240 Volt (v)

Horizontal Rectangular Autoclaves

Price Range 12000.00 - 90000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Autoclave

Usage : Use For Industrial And Laboratory

Application : Industrial

Voltage : 240 Volt (v)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry